Plastic injection molding is among the most employed and versatile molding methods used in several industrial operations. A wide range of injection molding machinery is available in multiple pressure ratings, tonnages, and quality of the material. Depending upon the quality of the plastic resins and machine type, the injection molding can manufacture a range of objects, including small decorative to significant automobile parts.

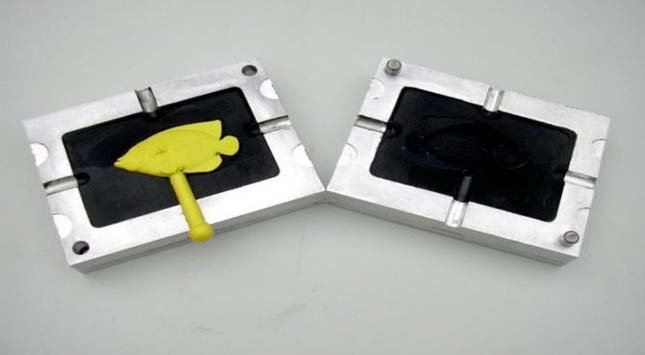

This injection molding process is capable of producing identical plastic objects in greater volume with excellent quality. In the molding process, the molds are made up of stainless steel or aluminum, and they are filled with molten plastic filaments.

With these molds, companies can produce hundreds of thousands of parts of consistent dimensions and aesthetics. Many companies now offer large-scale industrial plastic injection molding in Brisbane and other cities to fulfill the growing demand.

Plastic Injection Molding Process

This advanced molding process utilizes pelleted or granular plastic resins for manufacturing products. Be it automotive parts, or custom airplane tools, or storage containers; this process covers a wide range of applications.

Another reason why this manufacturing process is widely used is its less complicated working operations. This molding process leverages a vast range of plastic filaments including polypropylene, acrylic, polystyrene, and more.

Clamping and Injection Process

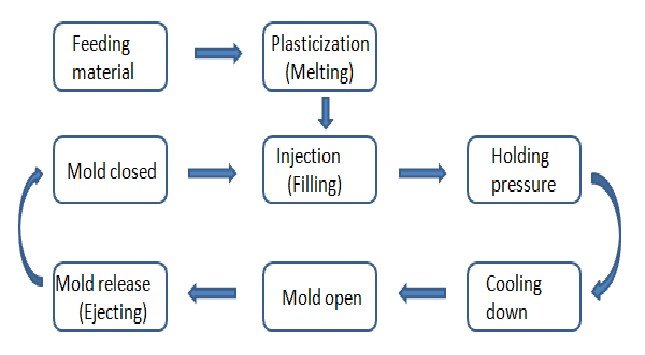

The majority of the molding equipment needs a short process cycle for producing one object. Clamping is the initial stage of that manufacturing cycle that includes a hydraulic unit that secures aluminum or steel molds halves before the plastic filament is injected.

In the main injection stage, the plastic filaments are molten down through heat and intense pressure until they arrive at the step of injecting. ‘Shot’ is referred to as the amount of plastic that has been injected into the steel or aluminum mold halves. The machine operator calculates the injection times with the help of injection power, shot volumes, and injection pressure.

Solidifying and Ejection Process

As soon as the molten plastic is injected, and comes in contact with the mold surface, the filament starts to cool and gradually solidify. During this process, a minor amount of shrinkage also occurs due to the cooling process. However, the packing of the filament during injection helps extra material to enter the mold to prevent the object’s original shape from damage due to shrinkage.

After the object reaches a stage where it is sufficiently solidified, the ejection system of the equipment takes over the process. It opens up the molds and pushes the freshly-made object out. The machine employs a high force to move the item out from the mold in a clean manner without damaging the object’s surface.

The ejection time of the object is based on dry cycles and the time needed for the item to get entirely out from the molds. After this, the molds are clamp shut and then moved towards the injection process again.

Quality Control

Final objects made using the plastic injection molding equipment may share some common defects because of the machine’s inaccurate settings. Very high injection pressure or excessively low clamp forces are among the common issues faced in plastic injection molding.

If the cooling cycles are not synchronized, warping may occur, and on the other side, excessive moisture can produce bubbles on the object’s surface. So, it becomes instrumental in conducting the manufacturing process after ensuring correct machinery settings and production environment.

Correct Designing of Plastic Injection Molding Parts is Instrumental

Preparing the plastic injection molding design needs a deep understanding of how this process works. Instrumental skills are necessary for avoiding manufacturing defects and ensuring higher accuracy. From the designing process to prototyping and testing, everything matters during manufacturing.

Only the accurate design can deliver high-quality plastic products in volume without any defects or performance issues. Below are some of the essential aspects of plastic injection molding that needs to be aligned with higher accuracy:

- Vent placement

- Corner transitions

- Weld lines

- Rib design

- Wall thickness

- Boss design

- Gate placement

Tips for Picking the High-Performance Materials:

Plastic materials play a significant role in the final product’s overall quality. Before you begin your search for 3d Printing Supplies in Brisbane or another city you live in, there are a few things to keep in mind. With a robust advancement in this manufacturing industry, you will find a wide range of materials. So, before picking plastic materials, below are some key aspects to consider:

- Depending on the requirement, make sure you pick the right color, texture, and transparency of the material.

- Flexibility and rigidity are critical for your product’s life, and you have first to research a bit before you finalize the materials. You can consult any Injection molding company near you in Brisbane or other cities to ensure you are buying the right materials.

- Based on your purpose, check if your plastic is meeting the respective compliant, including NSF, RoHS, FDA, REACH, and more.

Costs of Plastic Injection Molding

If you are planning to set up your manufacturing assembly, it’s crucial to have an idea about the overall investment. The cost of plastic injection molding varies depending on multiple factors, including the complexity of the design, injection mold materials, cavities, and more. Following are the key factors that influence the costing:

- Cycle times involved in the overall process

- Part size of the manufacturing item

- Type of resin you are using for the production

In simple terms, the plastic injection molding cost goes down when you scale up the production volume. That’s why most of the industries prefer this injection molding for higher volume manufacturing. This technology is getting more advanced with the involvement of innovations, and plastic injection molding is here to stay.

This process can match the growing demands of products, ensuring high-quality. This technology is a boon for both small and medium-sized industries along with large scale plants. Many 3d printing hubs offer professional SLA services in Brisbane and other areas to help businesses scale their production. This cost-effective manufacturing method is going to be the future of advanced mass manufacturing with high-quality standards.