In modern times case packers are used in many industries. In early times it was only used in food processing units. You can see its use in various pharmaceuticals, automobiles, toy manufacturing, etc. There are many types of case packers available.

In there you can, you can load your cases by the bottom, sides, and top. The reasons to select side load case packers are that they can increase the production line. It is a machine that is used for bag in box type of packages.

It can speed up the whole packaging process. To improve packing, you can install an automatic packing machine. It can save time and money.

Why Side Load Case Packages are Popular?

Using sideload case packers, you can pack around 100 products in a minute. The machine will load your products by a conveyor, wrapping them up with a secured film. When the products are packed successfully, these machines drop the products inside the tray.

The Uses of a Side Load Case Packer

- You can use it for different types of goods.

- It can be used to pack chemical products or liquid in pouches.

- You can also use these case packers to pack your food products like meats, cheese, and dumplings.

These packers also come in different shapes and trays. In these packers, you can use bags with a flat surface.

Design

The compact design of this machine can give you direct access to the ground level. These case packers are designed with plates to ensure that your products will not fall. You can keep your products safe and prevent them from unwanted damage and wastage.

Synchronization

You can get some load case packers that can synchronize with other devices. Here you can make one or more case makers in the production line. You can also use several machines to produce the same product.

You can add single case packers with different product units, and they can load from the different zone and then pack them to your desired specification. It is hard to invest in the case of packers for the different production units.

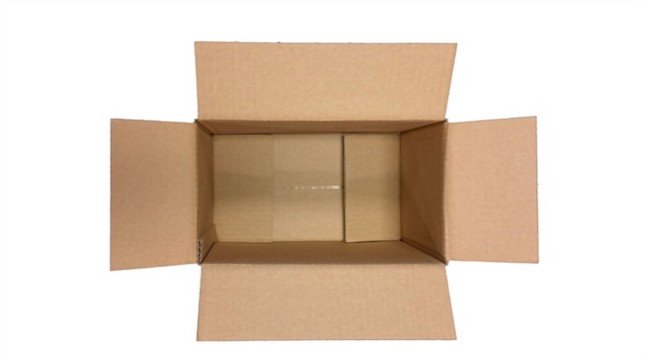

In the side load case packers, you get a flat blank loading case. You need to change these cases if they are filled with your products. There are some packers available that can hold up to 200 cartons on a loading case.

You also can change their cases by making use of the wheels. In 30 minutes of change over time, these case packers will be changed. In selecting case packers, you must find one that has sensors and speed adjustment tools. You can adjust the speed using a remote-control system in this machine.

How Do You Select Case Packers?

There are several types of cases available. You need to select the best for your products. There is top load, wrap around and sideload case packers. These are common machines in the industries.

You can select the best according to the product type. The top-load packer is used for packing bottles filled with liquids. The wrap-around packer is used as a case packer for packing breakable bottles and containers.

You can pack some products by sliding through them using the case packer, like soap, bars, and boxes filled with dried pasta. You can also use them to pack many more items.

Final thoughts

Packers gather more information online before choosing one of these side loads cases. You can ask people who have used these kinds of similar products.

You can connect with various companies and ask them questions about their product. If you feel satisfied, then you can go to buy these products.